|

|

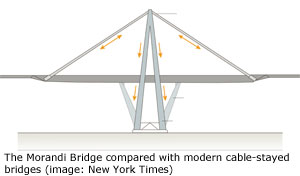

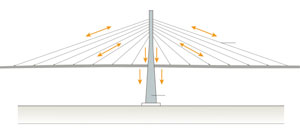

Dirk Rinze Visser MSc CEng RC and Thomas Eckhart MEng CEng MICE, both working at BuroHappold Engineering in London, United Kingdom Although the cause of the Morandi bridge collapse in Genoa, Italy, is not yet confirmed, lessons can already be learnt from this catastrophic event. On the back of “Genoa” and a near-miss in the UK, an international perspective on structural safety is illustrated with examples from the past, present and future. MORANDI BRIDGE, GENOA, ITALYThe Polcevera Viaduct, otherwise known as the Morandi Bridge, named after its designer Riccardo Morandi, is a cabled stayed bridge completed in 1967. During a thunderstorm on the 14 August 2018, the bridge partially collapsed, killing 43 people, and leaving a huge gap in both the local community and Italy’s strategic road network. First of all, it must be stressed that the investigation into the cause of the collapse is ongoing and until the investigation is complete, it is only possible to speculate. Some possible reasons of the collapse (adverse weather, increase in traffic demand and age of the construction) have been identified immediately after the tragic event, but maintenance issues, general deterioration of the structural system and presence of corroded stays have also been highlighted by experts. STRUCTURAL SAFETY OF BRIDGES IN THE UKThe Highway authorities in the UK undertake regular inspection of bridge structures and they place emphasis on durability and maintenance in their design standards. These measures have generally proved satisfactory in maintain the UK’s road infrastructure. At a local level, recent research by the RAC foundation has found approximately 3,500 local council-maintained road bridges to be substandard, representing 4,6% of the UK total. Many of these bridges have weight restrictions and are under programmes of increased monitoring. Despite the relative health of bridges in the UK, there have been several high profile nearmisses, demonstrating that the UK is not immune to the problems faced by bridge engineers worldwide. According to the New Civil Engineer, the UK have experiences five near-misses in the last 15 years, including the Forth Road Bridge spanning the Forth outside Edinburgh, Scotland.

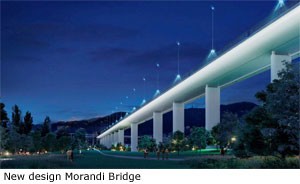

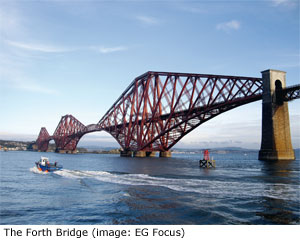

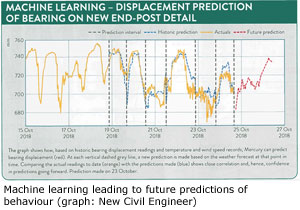

These bridges provide an interesting array of examples of the issues around bridge maintenance and present an evolution in the attitude taken towards long term maintenance at the design stage of bridges. THE FORTH BRIDGEThe Forth Bridge is a steel cantilever rail bridge designed by John Fowler and William Barlow, and constructed in 1890. It is the first major structure in the UK to be constructed from steel. FORTH ROAD BRIDGEThe Forth Road Bridge is a long-span suspension bridge and was opened in 1964. At that time, the bridge had the fourthlongest main span in the world (1006 m). Its deck supports a dual two-lane carriageway and there is a separate footway/cycle track on either side. About 25 million vehicles now cross the bridge each year, more than twice the amount of traffic it was designed for. In contrast to its heavy 19th century neighbour, the Forth Road Bridge presents an efficient lightweight structure. However aspects of the attitude of ‘build and forget’ was still present during its design, and within less than half of its original design life, the bridge began to show signs of significant deterioration. One of the major issues to affect the bridge has been corrosion of the main suspension cables. Unfortunately, there is no other way (yet) to inspect the main bridge wires than to take the wrapping wire off and to open up the cables. In this respect the Forth Road Bridge bears similarity to the Morandi Bridge in Genoa. QUEENSFERRY CROSSINGThe Queensferry Crossing is a new cable stayed road bridge opened in 2017. The 2,7 km structure is the longest three-tower, cable-stayed bridge in the world and also the The strands that make up the stay cables can be individually replaced without the need to restrict traffic on the bridge. The bridge has also been equipped with an advanced structural health monitoring system: about 1000 sensors have been installed to monitor the global behaviour of the bridge and its environment in real time (wind, temperature, corrosion, motion and any strains). This allows the operator to respond quickly to extreme events, to target inspections and to carry out pre-emptive interventions to avoid potential failures. Recently machine learning has been added to largest to feature cables which cross at midspan. This innovative design provides extra strength and stiffness, allowing the towers and the deck to be more slender and elegant. The bridge presents an evolution in the attitude towards long term maintenance in bridge design. From the outset the design has sought to integrate whole life maintenance, with considerations given to monitoring condition and behaviour and to facilitate the repair and replacement of components if required. the software which will enable it to use historical data to identify trends or behaviours not yet recognised by the maintenance team. It will take time to collect data to make meaningful predictions, but it is expected that the software will be able to make predictions about what safety measures or repairs should be carried out in advance of forecasted severe weather events. In addition to advanced monitoring systems, advances in technology are also been utilised to improve traditional visual inspections by engineers. A virtual reality (VR) model of the bridge has been created and the maintainers are trialling the use of VR by engineers to view 360° camera footage captured by drones on site. The use of such technology in bridge inspections is still new, but the Forth Road Bridge and the Queensferry Crossing are at the forefront of these developments in the UK. The latest technologies are helping to maintain the structural health of both bridges and allowing both to be brought into an integrated ‘managed crossing scheme’ safeguarding the future of this vital road link. MAKING THE VISION VIABLEBuroHappold Engineering designs bridges without disregarding future maintenance. The whole life approach to bridge design is key in each design, including the one for the Northern Spire in Sunderland. Forming a major part of the regeneration of the North East, the Northern Spire - an imposing two span cable-stayed bridge with an A-frame pylon - is the first new road bridge in Sunderland for more than 45 years. Crossing the River Wear, it carries two lanes of traffic in each direction, together with dedicated cycle ways and footpaths, creating a much-needed safe passage for all modes of transport. The Northern Spire is designed to minimise maintenance requirements and to facilitate ease of maintenance. All elements of the bridge are detailed to cater for future access requirements of a principal inspection. Key areas with regard to access are both the adjustable and fixed end anchors locations at deck level and within the pylon respectively. The access has been fully integrated into the principle structure. Openings in structural members have been consider in the design and detailing of these along with all fixtures, fittings and clearances required for access. Besides facilitating access for inspection and maintenance, it has also been ensured that all inspection and testing equipment are catered for in the design and in the detailing of the bridge. Platforms, ladders, guardrails, internal lighting and power sources have all been provided. Connection points have been provided on the steel pylon for installation of a proprietary scaffolding system for access to the external pylon. The inner face of the pylon is to be accessed by abseiling. Lessons have been learnt from the past and the below mentioned technical enhancements have been incorporated in the Northern Spire, and these could also be considered in future bridge designs as well:

It is up to us, architects and engineers, to prevent disasters like in Genoa and nearmisses like in Edinburgh, and to assure structural safety and breath-taking bridge design continues to walk hand in hand for generations to come. |