|

|

Prof. Dr. sc.techn. Mike Schlaich,

Technische Universität Berlin, Germany, www.massivbau.tu-berlin.de

Schlaich Bergermann Partner, www.sbp.de

Dit artikel beschrijft het ontwerp en de bouw van het nieuwe landmark over de Yamuna Rivier in New Delhi. De 675 m lange, a-symmetrische tuibrug met een VVK-dek en een achterover hellende pyloon is onderdeel van grootschalige, infrastructurele werken in de hoofdstad van India, waarvan de voltooiing in 2018 wordt verwacht.

Omdat het de eerste buitenlandse inbreng op een Bruggendag is, is het artikel in het Engels opgenomen.

OUR BRIDGE HISTORY IN INDIA

As early as in the 1970s, Jörg Schlaich together with Rudolf Bergermann (the two founders of our office) designed the Second Hooghly Bridge, nowadays called Vidyasagar Setu, in Kolkata (Calcutta), with a then record span of 457 m [1]. Another early cable-stayed bridge is the much smaller Sikkim Bridge in Akkar which was built in 1988 in a remote area which was difficult to access. What both bridges have in common is that they were built indigenously, with local labor, local construction methods and local material. For the Sikkim Bridge even the cables were manufactured on site! Vidayasagar Setu was also the first cable-stayed bridge with a composite deck and it has become the origin of many such long-span cable-stayed bridges all over the world.

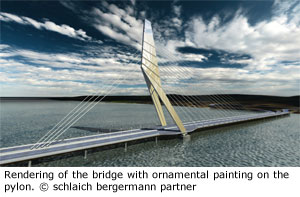

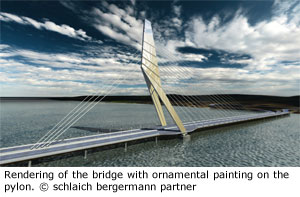

Now, more than forty years later, another large cable-stayed bridge crossing the Yamuna river in New Delhi is nearing its completion. Globalization has it, that today also in India indigenous building has to be redefined and other issues such landmark designs have surfaced. The Yamuna Bridge is envisaged to become an attraction that will serve as the starting point for a recreation area in the Indian capital and which will improve quality of life in an area burdened by

pollution.

DESIGN AND CONSTRUCTION OF THE YAMUNA BRIDGE

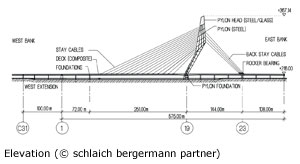

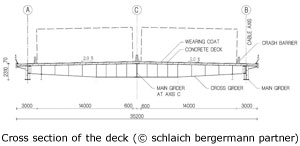

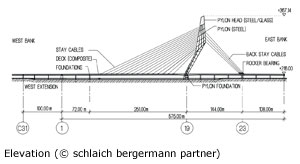

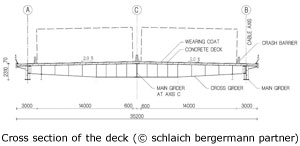

The ‘Signature Bridge’ as the new landmark of New Delhi connects the city Ghaziabad and its surroundings across the river Yamuna to Delhi’s the inner city. The asymmetric cablestayed bridge has a main span of 251 m (corresponding to a symmetric bridge with two pylons of 500 m span) and a total length of 675 m [2]. Its composite deck carries 8 traffic lanes (4 in each direction) and is approximately 35 m wide. The main span is supported by lateral cables spaced at 13,5 m intervals. Towards the approaches the same deck section continues with piers supporting it at 36 intervals. The height of the steel tower is approximately 150 m. The dynamically shaped pylon consists of two inclined legs, which are rigidly connected to the deck girders and bend mid-way. The upper portion of the pylon anchors the backstay cables as well as the main-span cables, arranged in a harp like manner. The tip of the pylon is created by a 30 m high steel-glass structure, which can be illuminated to create a beacon visible from afar at night [3]. A special detail of the bridge is that the selfweight of the pylon partially balances out the self-weight of the superstructure through the

eccentric location of its center of gravity with respect to the pivot point of the pylon footing. This serves well to reduce the load on the back-stay cables. The fact that the modules were bolted together on site instead of welded is an adjustment to the local methods of construction. Construction started 2010, meanwhile all the 13,000 t of structural deck and pylon steel have been fabricated in China and shipped to the construction site. By the end of 2017, most of

the deck and the pylon were erected with half of the stay-cables installed. The bridge deck consists of three main girders with a height of 2 m and cross girders at a spacing of 4,5 m. To provide sufficient space for eight lanes, the two outer main girders, supported by cables, are spaced 32 m apart from each other. The emergency footpath has been placed on 1,5 m long cantilevers outside of the cable planes. All main and cross girders are welded I-sections with plate thicknesses between 20 mm and 100 mm in grade S355. To save material the cross girders have a variable depth with a maximum value of 2 m in the center and 1,4 m at the connection to the outer main girders.

Similar to the Ting Kau Bridge in Hong Kong [4], all joints have been designed as bolted high strength friction grip connections. In addition to that the outer main girders are in butt contact in order to transmit the compression induced by the horizontal component of the cable force via contact and not the bolts. The contact was achieved by machining the end faces of each girder which saved a lot of bolt and splice plate weight. No machining was required for the central main girder splices since it mainly redistributes local wheel loads.

The deck of the Signature Bridge in New Delhi is located relatively low above water which is shallow outside of the monsoon period. Therefore, it was possible to erect the entire deck on temporary trestles and to install the cables only afterwards. Thus, full composite action also for dead load could be achieved, so that the concrete slab is transmitting even more compression force as in the other cases. This is reflected in the distribution of the concrete slab thickness. Outside of the cablestayed part the precast reinforced concrete panels have a thickness of 250 mm which gradually increases to 350 mm thick panels towards the pylon and ends in a 700 mm thick in-situ portion around the pylon legs.

The deck panels are made of grade M50 concrete (similar to C40/50 in terms of Eurocode) with a size of 4,5 m by 8 m to minimize the number of transverse joints. Due to the positive experience gained from the joint detail developed for the Ting Kau Bridge (see [4]) the same detailing has been used again. For the areas outside of the cablestayed part the detail was further developed to allow for a central layer of reinforcement between the top and the bottom reinforcement. The three layers of reinforcement cover the axial tension in the slab, created by the negative bending moments above the piers. The rigid connection between the concrete slab and the steel girders was achieved by

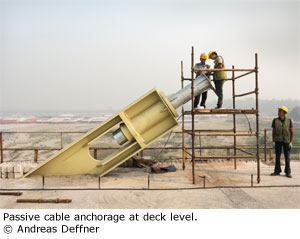

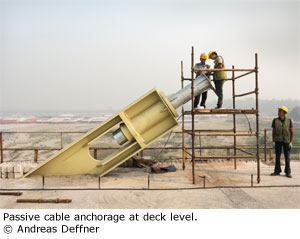

shear studs with different diameters for main and cross girders. To transmit out-of-plane shear forces, the end faces of the panels have been treated in such a way that the cementitious grout was removed and the coarse aggregate became visible. Furthermore, pockets have been foreseen in the end faces of the panels to transmit the significant in-plane forces safely. A state-of-the-art stay cable system with diameter 15,7 m strands made of steel grade 1860 has been used. Up to 128 strands form one stay cable. Since no fatigue tests for the largest anchor type were available with the supplier Tensa, such tests were performed especially for this project. The larger active anchors are all incorporated in the interior of the pylon while the more compact passive anchors are located above the concrete where they can easily be inspected and maintained.

SUMMARY

Forty years ago cable-stayed bridges with composite decks were indigenously built in India for urban and easily-accessible areas like Kolkata as well as in the remote areas of India in Sikkim. Over the years detailing and building methods have evolved, e.g. from rivets to high strength bolts or from in-situ concrete decks to accurately fabricated precast panels. Durable and safe cable systems which comply with international standards have replaced in-situ made

solutions. The same applies to large scale bearings, expansion joints as well as monitoring and maintenance equipment. The new Signature Bridge in New Delhi will be a flagship project representing state-of-the-art construction possible nowadays in India combined with international engineering experience.

REFERENCES

1 SCHLAICH J., BERGERMANN R., ‘Cable-Stayed Bridges with Composite Stiffening Girders - The Second Hooghly Bridge in Calcutta’, Proceedings of the Sino-American Symposium on Bridge and Structural Engineering, Peking, 1982.

2 SCHLAICH M., BURKHARDT U., ‘Composite decks for long-span cable-stayed bridges’, The Bridge & Structural Engineer, Volume 46, Number 2, INGIABSE, New Delhi, 2016.

3 SCHLAICH M., SUBBARAO H., KURIAN J., ‘A Signature Cable-Stayed Bridge in India - The Yamuna Bridge at Wazirabad in New Delhi’, SEI Journal, 1/2013.

4 BERGERMANN R., SCHLAICH M., ‘The Ting Kau Bridge in Hong Kong’, Proceedings IABSE Symposium Kobe, Japan, 1998.

DATA BLOCK

| Yamuna Bridge in New Delhi, India |

| Owner/Client |

Delhi Tourism and Transportation Development Corporation (DTTDC) |

| Conceptual and structural design |

schlaich bergermann partner, Germany |

| Cooperation |

Construma Consultancy Pvt Ltd, Mumbai (foundations);

Ratan J. Batliboi - Consultants Pvt Ltd, Mumbai (architectural advisor) |

| Wind Tunnel Studies |

Wacker Engineers, Germany |

| Seismic Studies |

IIT Roorkee |

| Checking Engineer |

Systra and M.Virlogeux, France in association with Tandon Consultants, New Delhi |

| Construction |

Joint-Venture Gammon-Cidade-Tensacciai |

Download hier het artikel in pdf-formaat

|